INFRASTRUCTURE

As a Start-up, we are coming up with a facility that will meet the primary business load and are committed to its expansion to cater to wider markets and customer base over the next few years.

Fabrication, Welding and Quality

- 20,000 sq. ft facility under construction (Expansion feasibility for another 20,000 sq. ft adjacent facility)

- Pipe bevelling tools and tackles for precise surface preparation for fit-up & welding purpose

- Plasma & Oxy acetylene cutting equipment(s)

- Hydro and Pneumatic test equipment suitable for pressures up to 200 bar

- 4 Roll Plate rolling machine with PLC control system For precision pre-pinching & rolling requirements

- Roller beds suitable for 30T capacity (Larger capacity available at short notice)

- Column and Boom system

- Inverter-based SAW machine

- Qualified welders as per ASME Sec IX, AWS D1.1

- ASNT TC-1A qualified NDE personnel and Level II

- In-House capability for PT, MT, PMI requirements

- In-House Blasting & Painting facility

- RT and UT through certified agencies

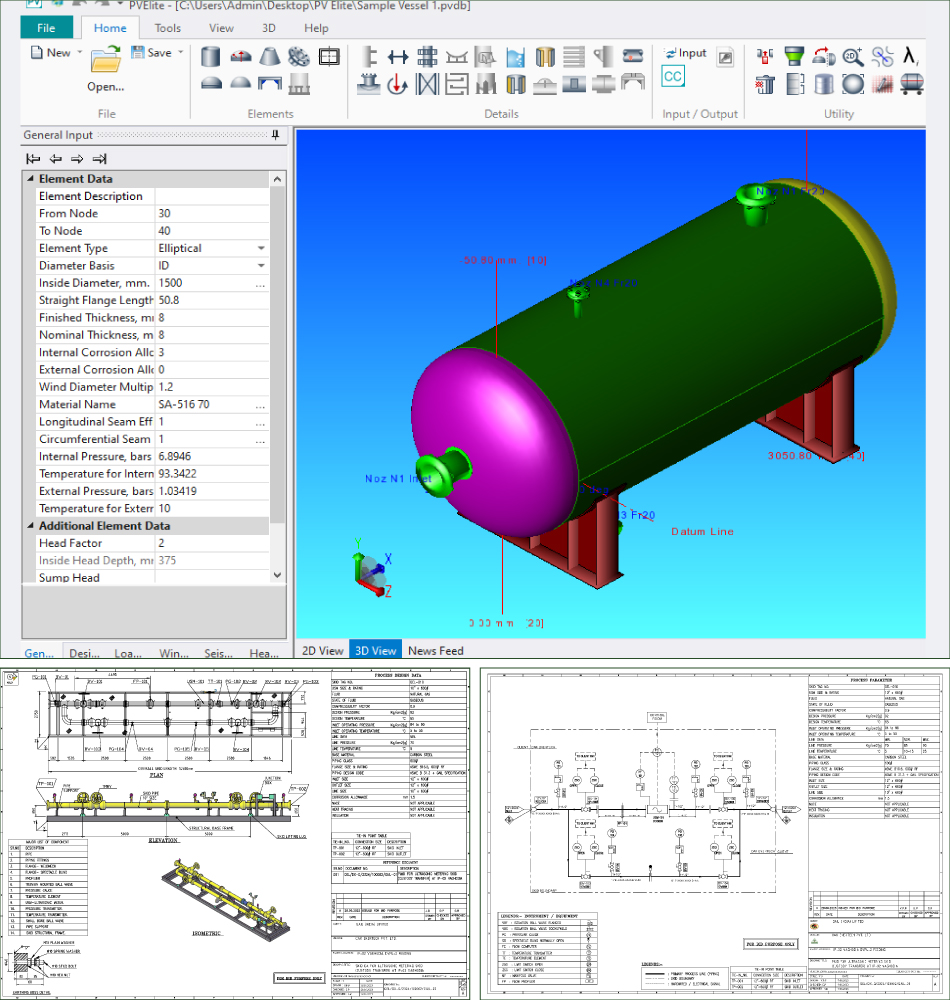

Design & Engineering

- In-House capability for ASME Code Vessel and Heat Exchanger Calculations and Analysis using PV Elite V25 software

- In-House AutoCAD capability for Process & Instrumentation diagrams (P&ID’s)

- In-House Design Engineering capabilities in Mechanical Design, Electrical and Instrumentation design having PLC based Control System